Content Overview

- Improving Business Case of GIS & SAP Integration

- Using GIS to Overcome SAP Challenges

- Workflow Process Continuation & Automation

- Plan Work Process

- Create Work Process – Automatically

- Schedule Work Process

- Dispatch to Field & Complete Field Work Process

- Monitor All PM Programs Process

- Regulatory Compliance Reporting Process

- Summary

Improving Business Case of GIS & SAP Integration

UDC strengthens the GIS/SAP integration business case with a solution for lowering the implementation cost of doing the integrations and total operating costs by automatically maintaining the utility’s business process’s planned work and preventative maintenance programs. We can reduce the overhead and maintenance cost of the interface by lowering the complexity of the GIS/SAP asset synch integration and the amount of data being synchronized between GIS and SAP while still performing all required surveys, inspections, and planned maintenance work through the use of Digital Utility® Compliance Manager.

The Compliance Manager solution works for gas, power, water, and wastewater utilities. For this article, we will use examples from the gas utility domain. The key takeaway for you, our reader, is that the Digital Utility® Gas Compliance Manager® paradigm supports getting all planned work, including inspections, surveys, and planned and preventative maintenance (collectively labeled as ‘PM programs’) visually planned and monitored via the GIS and maintaining the PM programs automatically during the as-builting process while recording the work status and asset condition in SAP.

Using GIS to Overcome SAP Challenges

For existing SAP users, Digital Utility® Gas Compliance Manager® can be used to geocode all existing PM programs defined in SAP. Once within the Digital Utility® Gas Compliance Manager®, all of the SAP challenges as mentioned by the SAP/GIS white paper including:

• Lack of geographic location and mapping capablitiy

• Inability to determine the number of assets within a geographic boundary

• Inability to view similar work orders nearby

are resolved by the user visually using the GIS to utilize geographic boundaries (map grids, street buffers, operating areas), facility geometric networks (hydraulic independent pressure systems) and linear referencing (transmission line ranges) to organize their surveys, inspections and maintenance work based on these intuitive work boundaries and to aggregate up into larger groups for job assignments if that is most efficient for an organization. This allows monitoring and reporting to be based on geographical or operational system based GIS areas and then aggregated up via the company reporting hierarchy as well.

Workflow Process Continuation & Automation

Supporting New Asset Construction Process

Vesta discusses how SAP and GIS can be integrated from a new construction point with work orders or notifications being created in SAP, job designs laid out with a GWD tool in the GIS and compatible units and job conditions sent to SAP for material requisitions, job estimating and job scheduling. The GIS based field redlining tool is used by the crews in the field to redline as-builts and record what was installed, where and send that data back to both GIS and SAP to support future materials traceability queries and to utilize SAP’s serialization and batch materials traceability functionality.

Supporting Planned Work for Asset Management Process

The Digital Utility® Gas Compliance Manager® picks up where the above construction workflow ends. As the facilities go into the ground and get placed into the GIS as part of the utility’s normal as-built GIS based process, the Digital Utility® Gas Compliance Manager® automatically assigns all new assets to the defined set of PM programs that they belong in and removes all old assets that have been removed from the field from PM programs they belong to. A key feature of the Digital Utility® Gas Compliance Manager® is not just synching PM programs based on assets being added, moved, and removed; however, it also automatically moves assets to other PM programs if the PM programs’ work areas are changed. This type of automation, based on both asset attribution criterion and work area spatial criterion, is a big challenge within SAP and tends to drive up the day-to-day O&M management of PMs when solely managed in SAP.

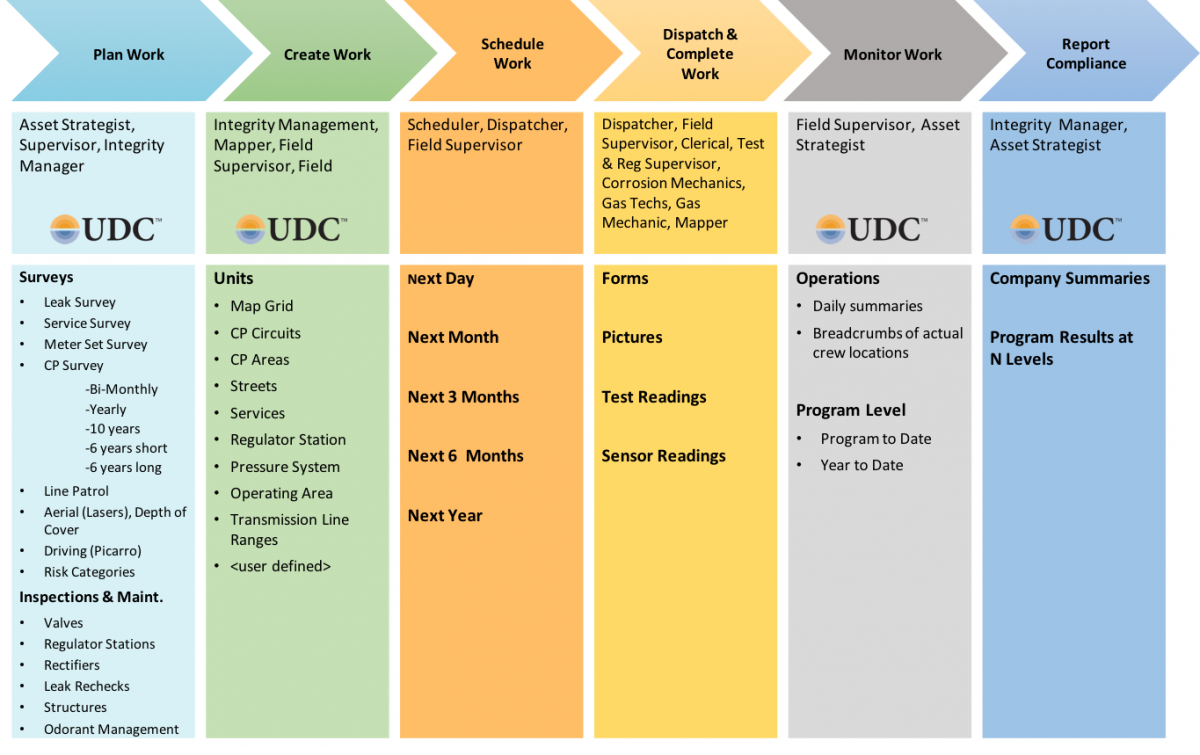

The diagram below portrays the high-level business process of performing gas planned work for surveys, inspections and maintenance. It should be noted that the Gas Compliance Manager® solution is a single software framework on top of the Esri ArcGIS Enterprise Platform and has been designed to be highly configurable. This enables gas utility asset owners to define asset management policies and to enforce them consistently by utilizing a common asset management paradigm for all asset classes that takes advantage of the visualization power of GIS to plan work and monitor work and to bring mobile GIS functions to the field workers leveraging the power of the Esri ArcGIS Enterprise Platform.

Each of the chevrons within the workflow diagram are expanded on to highlight the functionality that the Digital Utility® Gas Compliance Manager® brings as well as the recommended approach for integrating with SAP and possibly mobile workforce management (MWM). Since the integrations are all web services based, those highlighted for SAP can be used with other Enterprise Asset Management/Enterprise Resource Program vendors as well.

Plan Work Process

This key process ensures work is well thought out and takes advantage of GIS visualization to improve the work plan. This process is lacking formalism at most utilities using just SAP to define their PM programs and is a perfect fit to take advantage of GIS technology.

During the ‘Plan Work’ process the following tasks are completed:

• User defines all PM Program Types or loads existing PM definitions from the utility’s SAP (EAM)

• Each PM Program Type has a set of activities and a set of associated standard operating procedures (SOPs) via integration with Content Management System

• User instantiates a PM Program Type graphically via the GIS as a PM Program. User selects a street, map grid or range of transmission line and schedules all survey work along or within the graphical area

• User instantiates a PM Program Type graphically and to include all asset types, a query predicate qualified subset of assets or to exclude a subset of assets based on a query predicate – i.e. all copper services, all cast iron pipe, etc.

• User defines what needs to be collected in the field for each activity – Field forms are automatically generated based on this action

• All surveys, inspections and maintenance programs can be setup and defined within this same process

Create Work Process – Automatically

The automation of the ‘Create Work’ process based on the definition of each PM program saves the utility on its O&M steady state costs. Large utilities using SAP can have over six thousand PM programs to maintain manually. The Digital Utility® Gas Compliance Manager® can be used to simplify the GIS to SAP asset synching process and to minimize the effort required to maintain all PM programs. The user should use the power of the GIS to define the management areas or the UNITS listed below:

- Map Grid

- CP Circuits

- CP Areas

- Streets

- Services

- Regulator Station

- Pressure System

- Operating Area

- Transmission Line Rangers

- <user defined>

If these do not already exist for all PM programs, UDC can assist with the creation of the required set of management areas to be utilized by all PM programs. The Digital Utility® Gas Compliance Manager® provides the flexibility for the user to create work areas based on any buffer, polygon, or even point feature location. This provides a visual and intuitive work around to overcome the SAP Functional Location limitations as stated in the Vesta white paper.

• User defines schedule for each PM Program

• Application creates events based on all PM Programs as defined

• Assets are added and removed from the GIS within As-Built process (these assets are also added and removed from all associated PM Programs)

• User can visualize all PM Programs using the Program module

• User can visualize all detailed events using the Event Management module

• Easily filter and sort the detailed events list using the Event Management module

Schedule Work Process

This is a natural designed integration point between the Digital Utility® Gas Compliance Manager® and SAP or the utility’s mobile workforce management (MWM) system for scheduling all of the work created by the Digital Utility® Gas Compliance Manager®. The scheduled date for all PM programs needs to be sent back to the Digital Utility® Gas Compliance Manager® to be used in its monitoring and reporting on progress displays.

• Typically the Digital Utility® Gas Compliance Manager® will be integrated with the utility’s scheduling system

• The Digital Utility® Gas Compliance Manager® will send the generated events to the utility’s scheduling system

• The utility’s scheduling system will send the schedule date for each event to the Digital Utility® Gas Compliance Manager®

Or for those utility’s without a scheduling engine:

• The user can setup a work schedule and route work from the Event Management application

• It is envisioned that both supervisors in the office and in the field as well as crews in the field will want access to Event Management application

Dispatch to Field & Complete Field Work Process

Most of our utility clients have good business systems to dispatch and complete the PM programs in the field. At a minimum, the Digital Utility® Gas Compliance Manager® needs the completion status and any exceptions raised by the crews in the field. Since the Digital Utility® Gas Compliance Manager® is an Esri ArcGIS Enterprise Platform application, it does come with a highly visual field work order completion module as well. This module brings both the utility’s landbase (reference layers) and gas facilities (operational layers) to the field so the crews can collect condition data about specific facilities but also work at the larger abstraction level by completing surveys at the work area level. The field component brings workflow integrations with SAP and Content Management System. The field component is GPS and gas survey aware which means a user can drive and complete their leak surveys with a start button and a stop button. While driving, the user is given feedback on both his speed and distance from the pipeline to indicate whether the survey is valid or not. The user is allowed to stop and grade leaks and associate leaks to features on their map. The Digital Utility® Gas Compliance Manager® field tool has integrations ready to initiate SAP repair notifications for grade one leaks and to automatically add grade 2 and grade 3 leaks to the already defined separate recheck PM programs defined within the Digital Utility® Gas Compliance Manager®.

• Typically the application is integrated with the utility’s SAP (EAM) or MWM to dispatch the work to the field

• Typically the application will be integrated with the utility’s system to get completion status information on a daily basis

• All condition data, attachments and job closing status data sent to SAP and CMS

• The field user can use a highly graphical native Esri 100.1.0 Runtime SDK based application on their tablet to record their inspections and complete their activities

Realized Benefits for Field Users

- Integrates with highend external GPS

- One button start/stop surveys with support for partial survey completion recording

- Works in both online and offline mode with caching/synching of maps and work orders

- Workflow support for SAP notifications

- Workflow support for grading leaks during surveys

- Workflow support for assigning leaks to gas facilities in the field

- Workflow support for auto assigning lower grade leaks to ‘recheck’ PM programs

- Workflow support for raising exceptions in the field

- Built-in integration framework for content management like SOPs, related drawings, condition assessment grading pictures, etc…

- Runs on Window 10 tablets and iOS iPads

Monitor All PM Programs Process

Gas Compliance Manager® brings consistency and visibility to all PM programs. Users are able to see both schedule and compliance progress. Supervisors, using the same tool, can drill down into exceptions being raised and create new PM programs to go back and gather data for the exception locations.

• The application is integrated with the utility’s SAP (EAM), MWM and CMS systems

• The user visually sees status of each PM program

• For multi-year programs, the user sees both year-to-date and program-to-date status

• Reports of exceptions (missed events) allow the user to easily track how much work needs to be done to remain in compliance

• Daily summary reports allow users to see how well crews are progressing

• User can view field generated breadcrumbs to verify field crew completed an event

Regulatory Compliance Reporting Process

By having the same tool used to plan, schedule, dispatch, complete and monitor compliance programs, the utility now has to spend zero time prepping for an audit. The auditing group can be given access to the Digital Utility® Gas Compliance Manager® to see current status of all PM programs against their compliance dates. This should add quite a bit of value to the business case as described in the attached article. Even if external users are not given access, when the auditors arrive at the utility, they can be given access then or walked through the Digital Utility® Gas Compliance Manager® Reporting module to perform their audits without the utility having to any initial prep work.

• The application provides a graphic view to support audits and regulators

• Full transparency – same tool used to plan, create and monitor work is used to report on it

• Uses power of GIS to aggregate program results

• No more time spent preparing for audits

Summary

UDC’s Digital Utility® Gas Compliance Manager® is designed to solve many of the challenges SAP has when trying to manage surveys, inspections and maintenance work that is based on geographical areas, facility geometric networks or linear referenced related assets. It is meant to be a framework that accelerates the integration of GIS and SAP and to act as the bookends of planning and scheduling the work graphically. It integrates with the utility’s SAP and has capabilities to integrate with its Mobile Work Management system to deliver the planned work to field crews while providing a highly visual monitoring dashboard of all PM programs. Gas Compliance Manager® gives the end user the ability to quickly filter and see only the PM program types and/or just a single operating area within the utility company.

By taking an as-builting approach to manage PM programs automatically, the Digital Utility® Gas Compliance Manager® enables a utility to define which asset classes they want to manage with a condition based maintenance paradigm and only synch those asset classes with SAP to utilize SAP’s condition based maintenance functionality while ensuring all planned work is being completed and recorded in SAP.

UDC agrees with Vesta’s business case value proposition for integrating SAP and GIS. We also believe the Digital Utility® integration approach allows utilities to grow into full utilization of what SAP brings to asset management by starting with a smaller set of asset classes that get synchronized with SAP based on those that utilities want to manage with a condition based maintenance first and allowing the Digital Utility® GIS as-builting approach be used to ensure all other asset classes and all safety related surveys are managed graphically, and all are being monitored graphically. Our approach provides full transparency of the compliance management and reporting process for the utility.

To learn more or request a demonstration of UDC’s Digital Utility® Compliance Manager, contact UDC or visit the Digital Utility® section of our website.