To maximize the benefits of deploying a model-driven Advanced Distribution Management System (ADMS), utilities must alter their business processes and supporting business applications to maintain ‘zero data latency’ with respect to field commissioning new portions of their distribution grid. Doing so enables all distribution grid changes to be part of the ADMS’s next run of system optimizations and ensures any Supervisory Control and Data Acquisition (SCADA) commands generated from the optimizations are based on the current network topology.

This article discusses how incorporating modern visual and graphical tools into your business processes and investing in a high-level of automation between your business applications will help your utility reach zero data latency and maximize the ADMS’s optimization of distribution grid configuration for energy efficiency, asset utilization, and self-healing responses to faults. Additionally, it highlights how your utility can effectively prepare its organization for the associated change to ensure a successful ADMS rollout.

Content Overview

Reaching Zero Data Latency

One way of attaining zero data latency in the ADMS is to send all construction designs being sent to the field for construction to the ADMS and all field generated as-builts to the ADMS via the GIS, such that the ADMS has both a proposed network model and an energized as-operating network model. That way, when construction is performed and portions of a job get commissioned and energized, the changes in the as-operating network model can be viewed in the ADMS by toggling an attribute rather than rerunning the ADMS Model Build Process to view the field updates.

A proposed network model also allows for proposed designs (defined by a proposed status) to be viewed in the ADMS which can help with the development of switching plans.

Graphical User Interfaces are Keys to Supporting Zero Data Latency

Incorporating automated graphical work design (GWD) and digital construction as-builting tools within the job design, digital construction field as-builting, and back office as-built recording processes drive the enforcement of the utility’s distribution data governance policies, thus ensuring the ADMS receives all proposed and as-built network model changes and all related power system characteristics in a timely manner.

Integral to supporting the required distribution data changes is providing ‘graphical’ data entry front-end interfaces as part of your business processes:

1. Job Design – A GWD tool should be used as part of the design process to ensure a new work order scheduled for construction has updated all the related systems that are providing the ADMS with the proposed (Pending Alterations) power system network information.

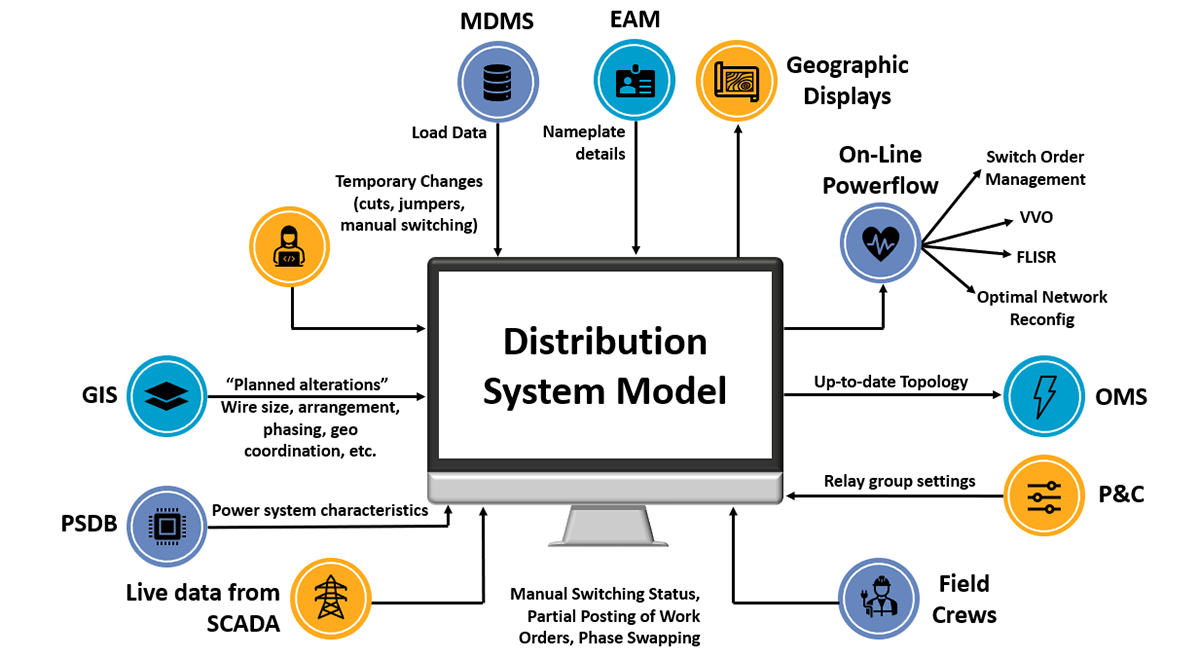

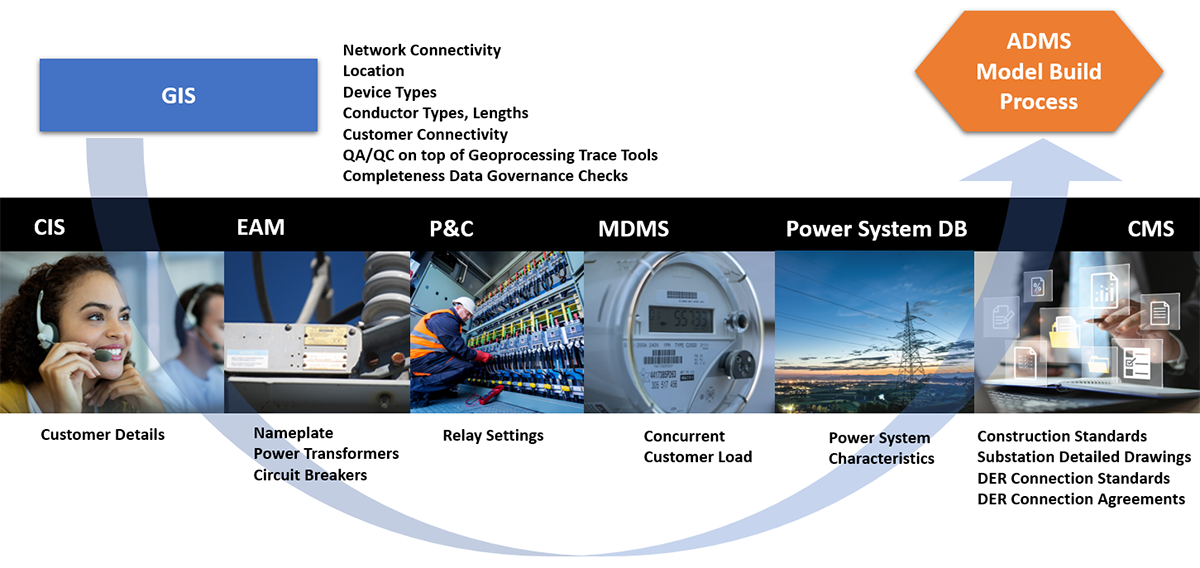

The goal of a GWD is to collect (but not replicate) all the facility information required to drive an ADMS as part of the integration with the ADMS’s Model Build Process. The GWD tool acts as the graphical data entry tool as well as the integration mechanism to get the required data to the GIS, Enterprise Asset Management (EAM), and Power Systems Database (PSDB). These systems together form the asset repository of the utility’s distribution power system network. The tool should include high productivity placement templates to allow the quick capture of new job designs.

The GWD needs to be integrated with all systems that manage:

- Compatible units and material units (EAM) – supports the generation of job estimates and bill of materials (BOMs)

- Facility nameplate data (EAM or PSDB)

- Facility asset characteristic information (EAM or PSDB)

- Protection and control information (P&C) – grabs information for the ADMS’s training simulator

As jobs get approved for scheduling, they must be sent to both the ADMS and the Digital Construction As-builting tool for the field to use. This gives the ADMS all the scheduled work orders as well as the current ‘nominal state’ or as-built view of the power system network, which allows the ADMS to know the new as-operating network topology as soon as the field communicates that new work orders are ready to be energized.

2. Digital Construction As-Builts – The Digital Construction As-builting tool is a simple graphical tool that enables field workers to redline on top of the graphic job design sent to them from the GWD tool. Through this, the field user can enter just the as-built changes and notify all systems who care (ADMS, GWD, GIS, EAM, ECM [Enterprise Content Management]) that a work order is ready to be energized. This process reduces the as-built recording time by sending as-built changes directly to the QA/QC environment of the enterprise GIS to be reviewed and posted, ensuring the ADMS is working on the most accurate and current ‘nominal state’ of the power system network.

When selecting a Digital Construction As-builting tool, utilities should look for flexibility in the tool to accept work from GWD, EAM, Mobile Workforce Management (MWM), GIS, and Customer Information System (CIS). It should input the information from these various systems into the nomenclature used by construction field crews. Additionally, the tool should accept related documentation from an ECM and be able to post data back to a GWD, EAM, MWM, GIS, CIS, and ECM based on the workflows needing field digital support at the utility.

3. Office Recording As-Builts – This should be the same GWD tool that was used to generate the design if the design engineer owns the processes of reviewing and updating job variances. The tool ensures that all as-built changes are updating all source systems concurrently via the same interfaces that posted the design version of this information to all relevant systems. This allows the ‘designer’ to own the job and run job variances.

Alternately, the GIS is a reasonable graphical tool for reviewing and posting field as-builts. Again, interactive QA/QC tools should be run in this environment and some ‘batch’ QA/QC tools should be potentially run as part of updating the related source systems.

Automating Daily Work Order Updates

A high degree of automation should be planned for the interface between the enterprise source systems and the ADMS and digital construction as-builts in order for the daily updates of scheduled and as-built work orders to run properly within the ADMS’s Model Build Process.

A daily change detection process must run in the GIS to group the related nominal changes and send the related group of changes to the ADMS’s Incremental Model Build Process. These activities should be monitored by an overarching system monitoring process to determine how long the process has been running and how long it will take the process to finish. That way, the user can stop and restart at checkpoints without having to restart from scratch. An administrator should review the log files to ensure the processes ran successfully without errors. Additionally, it is recommended that an analyst or engineer review the change set prior to input into the ADMS to ensure the quality of the changes. If it is discovered that the incoming changes could cause potential issues to the existing model, then this should be conveyed to the GIS team.

The distribution data processes in Figure 2 will form the majority of the interface requirements between the enterprise source systems (GIS, EAM, PSDB, P&C, ECM) and the operational systems (ADMS) regarding the level of automation expected.

In terms of the devices that exist in both the Energy Management System (EMS) and the new ADMS, the set of overlapping devices’ attributes (which form the Inter-control Center Communications Protocol [ICCP] interface list of tag ids) should be generated as well. We recommend a high degree of automation that allows the EMS to still own the creation and configuration of these points within its bulk power SCADA system. By putting the points into the GIS (typically by adding a tren name or SCADA id as an attribute of the device), the ICCP configuration for the ADMS side of the ICCP interface should be generated as part of the GIS/ADMS integration process so that both the ADMS network model and the EMS/ADMS ICCP integration configurations are maintained with the same amount of currency.

Achieve Organizational Readiness for ADMS

To successfully reach corporate objectives and mitigate risks on ADMS projects, it is paramount that business process owners and the eventual users are involved early in the distribution data change management business process changes, such as identifying and addressing the deltas from the As-Is to the To-Be processes for the typical ADMS workflows for planned and unplanned outages. Folding in the owners and users is key to employee acceptance of the technology and the ultimate success of the ADMS rollout.

For a systems integration project in which significant changes in organization-wide work processes and technology are taking place, critical business information must be conveyed to all employees – from top executive management down to the end user. Project employee communication is crucial for three primary reasons:

1. With or without formal communication lines, information will be disseminated throughout the organization ‘around the water cooler.’ However, if utility-sponsored information with adequate background and context is officially provided, the project’s impact on employees’ specific areas of operation can be effectively addressed in a positive manner.

2. Targeted, two-way communication reduces the risk of employees working at cross-purposes and provides a basis for employees to understand and meet the project’s objectives. The utility needs to include cross disciplinary change management discussions with the following system of record owners:

- Designers

- Asset managers

- P&C engineers

- Field construction crews

- GIS as-builting editors

- Customer service

- Power system engineers

- Knowledge engineers (potentially)

3. Communication is as much about expectation management as it is about education for a systems integration project, such as deploying an ADMS.

Also crucial to a successful ADMS project is ensuring all your business systems of record have the level of data quality to meet the requirements of the ADMS. Without the supporting data, the ADMS will be unable to run at full optimization.

Maximize Optimization Power of ADMS through Currency

As utilities plan for their ADMS projects, they should strive for zero data latency when it comes to the ADMS’s as-operating network model to reach the full benefits from their ADMS. Utilities can achieve this data currency through applying GWD and digital construction as-builting tools to their design posting, field as-builting/commissioning, and field as-builting recording processes and automating those processes between the business systems and the ADMS’s Model Build Process, thus ensuring the ADMS is up to date with all proposed and as-built network model changes.