Holistic electrical grid reliability analysis is critical for ensuring the reliable and resilient operation of the power grid, especially in the face of the electrification of the grid with distributed energy resources (DERs). Advanced analysis applications use sophisticated algorithms and data analytics to predict and prevent potential failures and disruptions in the power grid, while also accounting for the unique challenges and opportunities presented by DERs.

The use of advanced technologies and analysis tools in the grid infrastructure has led to the generation of large amounts of data that need to be analyzed to ensure continued grid reliability. When reviewing the results of numerous siloed data sets, it can be difficult for reliability engineers to efficiently process the analyses and make informed decisions about DER management and their asset management strategies.

The integration of Geographic Information Systems (GIS) and Business Intelligence (BI) tools with modern grid management systems and power system reliability analysis (PSRA) applications can solve the challenges posed by big data analytics. Leveraging these data management tools, utilities can integrate the data outputs from their reliability analysis tools and visualize the results spatially. Using a holistic enterprise approach to grid reliability and asset management is key to helping utilities to enable DERs safely and successfully on the grid.

Content Overview

- Traditional vs. Modern Reliability Analysis

- Predictive Analytics

- Risk Assessment

- Asset Management

- Building the Foundation for Holistic Reliability Analysis

- Transforming Feeder Analysis to Support Reliability Engineering

- Spot Grid Patterns

- Pinpoint Momentary Outages

- Detect Power Quality Issues Caused by DERs

- Identify Equipment Issues

- Applying GIS and BI to Manage Grid Reliability Strategies

- Holistic Reliability Analysis for the Modern Grid

Traditional vs. Modern Reliability Analysis

Demand response (DR) strategies are a critical tool for grid modernization, particularly in the context of managing demand during periods of high usage. These, coupled with the integration of DERs, which are vital for managing the formation of micro grids during storm events, introduce new challenges for reliability engineers.

Traditional tools for determining grid reliability, such as Fault Tree Analysis (FTA) and Failure Modes and Effects Analysis (FMEA), have been used for many years to identify the causes of outages. However, the integration of DR strategies combined with the increasing complexity of modern electrical grids, including DER integration, has rendered these tools insufficient. This is because traditional reliability analysis tools are not well suited to capturing the complex interactions between supply and demand-side factors that are crucial to understanding the impact of DERs on grid reliability.

To address the challenges with traditional reliability analysis tools, new tools are being developed that incorporate demand-side factors such as customer behavior and energy usage patterns. These tools use advanced analytics and machine learning algorithms to analyze large amounts of data on energy usage and customer behavior to identify patterns and predict future demand.

By using mathematical models to simulate the behavior of the grid under different scenarios and incorporating demand-side factors into the analysis, these tools provide a more comprehensive and accurate picture of grid reliability. This helps grid operators to quickly identify and address potential reliability issues before they occur.

For example, modern reliability analysis tools, such as PSRA, provide more detailed and accurate analysis of the grid’s reliability. Key aspects of PSRA applications are the modeling and simulation capabilities. Reliability engineers use mathematical models and computer simulations to analyze the behavior of power systems under precarious operating conditions. These models can simulate fault scenarios, load variations, and other events to assess system reliability.

The following tools and systems describe the different aspects of modern reliability analysis that reliability engineers and grid operators are performing today.

Real-Time Monitoring

Real-time monitoring systems are critical for ensuring the reliable and resilient operation of the electrical grid. These systems continuously monitor the performance of the electrical grid, collecting data on the flow of electricity, the status of equipment, and other critical parameters. They can detect abnormalities and outages in the electrical grid and provide early warning to grid operators to take corrective action. For example, if a transformer is overheating, the real-time monitoring system can detect the abnormal temperature rise and alert the grid operators before a failure occurs. The systems can also detect the location of faults in the electrical grid, allowing grid operators to dispatch crews to the location of the fault and restore power quickly.

Predictive Analytics

Predictive analytics tools use historical data and machine learning algorithms to identify patterns and trends in the data that can predict potential failures or disruptions in the electrical grid. These tools account for the intermittent and weather-dependent nature of DERs. For instance, if there is a significant increase in the demand for electricity due to high temperatures, predictive analytics tools can forecast the potential for grid overload due to the increased use of air conditioning systems. They can additionally predict the potential for outages due to equipment failures, such as transformers or switchgear.

Risk Assessment

Risk assessment tools evaluate the likelihood and potential impact of various scenarios that could lead to failures in the electrical grid. These tools consider the potential impact of DERs on the grid and identify the areas that are most at risk of failure, helping grid operators to prioritize maintenance and upgrades and ensure that the electrical grid remains reliable and resilient.

Asset Management

Asset management tools use data analytics and predictive maintenance techniques to identify equipment that is at risk of failure. These tools take into account the impact of DERs on the load and distribution of the grid and identify equipment that is at risk of failure due to increased demand or voltage fluctuations. As with the risk assessment tools, asset management tools can help with managing grid maintenance and upgrades.

Building the Foundation for Holistic Reliability Analysis

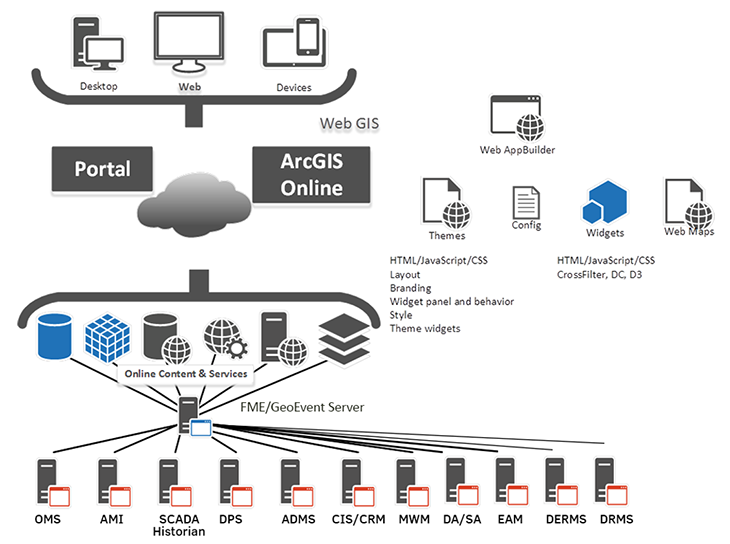

GIS, a computer-based tool that allows for the storage, manipulation, analysis, and visualization of geographic data, can provide thematic analysis of the results of both historical and forecasted reliability of the grid. This allows for the integration of spatial data with other data sources, such as data from the various reliability analysis tools.

For example, GIS can be used to create a map of the electrical grid that displays the location of DERs as well as the location of equipment that is at risk of failure. This enables reliability engineers to identify areas where the reliability of the grid may be compromised due to the impact of DERs. BI tools analyze and transform the data for consumption by the user, often in the form of operational dashboards.

GIS can also be used to visualize the results of risk assessments, allowing reliability engineers to identify areas that are at high risk of failure. By integrating data from predictive analytics tools, fault detection and diagnosis tools, and asset management tools with GIS, reliability engineers can prioritize maintenance and upgrades in areas that are at high risk of failure.

Furthermore, GIS can be used to analyze the impact of DR strategies on the reliability of the grid. DR strategies involve reducing electricity consumption during periods of high demand to reduce the strain on the electrical grid. By using GIS to analyze the results of DR strategies, grid operators can identify areas where the implementation of these strategies has had the greatest impact on the reliability of the grid.

Beyond visualization, GIS and BI tools support emergency management and response planning and grid resilience by providing the ability to model and simulate different scenarios such as the impact of different weather events on the grid. As a result, reliability engineers can develop and test contingency plans that can be put into action if the grid is affected by severe weather, ensuring that the grid can withstand different types of weather events or other potential disruptions.

Transforming Feeder Analysis to Support Reliability Engineering

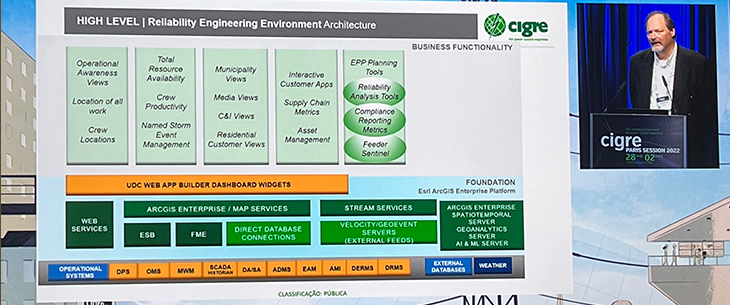

The integration of GIS and BI tools with modern grid management systems is transforming the way reliability engineering analysis is conducted. Advanced Distribution Management System (ADMS), Supervisory Control and Data Acquisition (SCADA), Distributed Energy Resource Management System (DERMS), Distribution Automation (DA), Advanced Metering Infrastructure (AMI), and Reliability Forecasting tools are some of the data sources that provide information to grid operators to enable them to identify and address reliability issues. By integrating these data sources and the outputs of their reliability analysis tools into a single platform, reliability engineers can receive a complete picture of the grid for more targeted and accurate asset management strategies.

In conjunction with the advanced reliability tools discussed earlier, historical data from ADMS, SCADA, DERMS, DA, AMI, and intelligent electrical devices (IED) monitored asset health information can be correlated with simulation-generated reliability forecasting information to provide a comprehensive and integrated reliability engineering analysis environment.

A key advantage of such an approach is the ability to look at the causes of historical outage events and correlate them with preventative maintenance programs conducted on substations and feeders. For instance, vegetation management programs can be correlated with historical weather patterns and the occurrence of outages caused by fallen branches or trees. Similarly, substation and feeder maintenance programs can be analyzed to determine their effectiveness in reducing outage events.

Incorporating data from SCADA, AMI, and IEDs in grid management strategies provide the following benefits:

Spot Grid Patterns

SCADA timeseries data can be used to detect patterns in grid performance and identify potential issues before they result in outages. By analyzing this data, grid operators can develop predictive maintenance programs that identify equipment that is likely to fail and address the issue before an outage occurs.

Pinpoint Momentary Outages

AMI information can be used to detect momentary outages and possible causes of the momentary outages. By analyzing this data, grid operators can identify areas where power quality issues are likely to occur and address them proactively.

Detect Power Quality Issues Caused by DERs

AMI data can also be used to identify power quality issues, such as voltage sags and swells. This information is extremely useful in detecting power quality issues caused by adding DERs on distribution power grids. Reliability engineers may use this information to add devices to improve the power quality along a section of the grid.

Identify Equipment Issues

IED non-operational asset health information can be used to identify issues with equipment before they result in an outage. By analyzing this data, grid operators can develop predictive maintenance programs that identify equipment that is likely to fail and address the issue before an outage occurs.

IEDs installed in switchgear can be used to take digital signatures of devices on feeders for predictive failure analysis, enabling grid operators to identify and address potential issues before they result in an outage.

Applying GIS and BI to Manage Grid Reliability Strategies

Another application of GIS and BI tools is to track the effectiveness of the utility’s reliability strategies, including reliability centered maintenance (RCM), asset condition-based maintenance (CBM) and CAPEX grid hardening programs. By providing the information necessary to drive these programs, utilities can improve the reliability of their power grids and reduce the risk of outages. However, it is important to remember that implementing these programs requires a significant investment in resources and a commitment to continuous improvement over time.

By analyzing data from a variety of sources, utilities can track the performance of their assets and identify trends that may indicate the need for further maintenance or capital investment. This information can then be used to refine and improve maintenance and capital investment over time.

Reliability Centered Maintenance

RCM is a process that aims to optimize maintenance strategies for equipment by identifying the most effective and efficient maintenance activities. This method prioritizes maintenance activities based on the risk of equipment failure and the potential consequences of such failures, ensuring that the maintenance activities undertaken are necessary, effective, and efficient. RCM requires a thorough understanding of the equipment and its criticality and a detailed analysis of the equipment failure modes and their impact on system performance.

The objective of the RCM process is to develop a comprehensive maintenance strategy that will reduce the likelihood of equipment failures and minimize the impact of any failures that do occur. Taking a systematic approach to maintenance, RCM can be used to optimize maintenance schedules, reduce maintenance costs, and improve the reliability and availability of equipment.

RCM can be applied to all types of equipment, from simple components to complex systems. However, it is typically applied to critical equipment, such as power transformers, circuit breakers, and other high-voltage equipment. The process involves identifying the potential failure modes of the equipment, determining the impact of those failures, and identifying the most effective maintenance activities to prevent those failures or mitigate their impact. This may involve the use of diagnostic tools, predictive maintenance techniques, or other strategies that are designed to reduce the likelihood of equipment failure or minimize the impact of any failures that occur.

Asset Condition-based Maintenance

CBM is a maintenance strategy that can be applied to improve the reliability of the power grid. One of the key benefits of CBM is that it allows for proactive maintenance rather than reactive maintenance. Unlike traditional maintenance strategies that are based on time-based or usage-based schedules, CBM is based on the actual condition of the asset being monitored. Maintenance actions are therefore triggered only when necessary. Through this proactive maintenance, potential issues can be detected and addressed before they become major problems. This approach ensures that maintenance resources are used effectively and efficiently, significantly reducing the risk of unplanned downtime, lowering maintenance costs, and improving overall system reliability.

CBM makes use of sensor data to continuously monitor the performance and condition of the assets in the power grid. The sensor data can be collected from a variety of sources such as smart meters, protection relays, temperature sensors, vibration sensors, and others. The collected data is then analyzed to detect any anomalies or deviations from normal behavior.

CBM can also be integrated with other data sources to provide a comprehensive picture of the asset condition. For example, CBM data can be correlated with historical maintenance data and operational data to identify patterns and trends in asset performance. This information can then be used to optimize maintenance schedules and improve asset performance.

Holistic Reliability Analysis for the Modern Grid

Modern electrical grid reliability analysis tools that account for the electrification of the grid with DERs are crucial for ensuring the reliable and resilient operation of the power grid. Integrating these modern grid management systems and PSRA applications with GIS and BI is essential for an effective reliability engineering program and the safe management of DERs on the grid. Correlating historical information from ADMS, SCADA, DERMS, DA, AMI, and IED monitored asset health information with simulation-generated reliability forecasting information, reliability engineers can identify potential issues before they result in outages and take action to address them proactively.

By meeting the unique challenges and opportunities presented by DERs with a holistic enterprise approach to grid reliability, we can help create a more sustainable, efficient, and reliable electrical grid that meets the needs of society today and in the future.

Connect with UDC to learn more about how you can effectively manage DERs and grid reliability through GIS and BI tools. For more material on taking an enterprise approach, download the eBook – Unifying Modern Grid Technologies within a Single Spatial Analytic Engine.