Project Highlights

- 4.3M Natural Gas Customers

- 21,000 miles Steel Distribution Pipe

In 2015, PG&E instituted a 5-year program to evaluate 21,000 miles of steel distribution pipe to determine location, cathodic protection status and ensure monitoring and tracking. Initial analysis revealed 3200 casings needed evaluation and 350,000 isolated steel risers required annual monitoring.

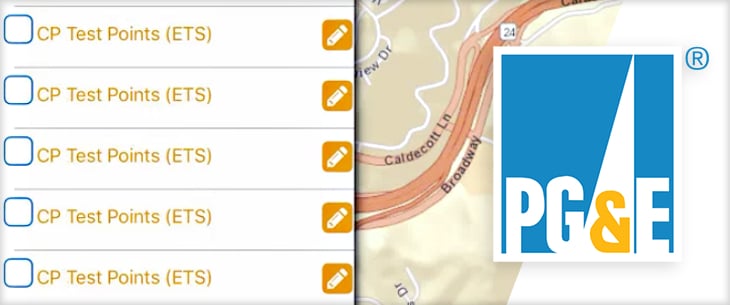

PG&E spearheaded the effort introducing the Compliance Manager solution for use by their CP Survey contractor transforming what was a labor intensive and paper reliant process in the past. PG&E had just completed their Gas Distribution GIS system and seized the opportunity to automate and streamline the update of their CP Program.

Using Compliance Manager, PG&E’s Isolated Steel Service Points (ISSP) assets are defined spatially and can be added to the program on an as needed basis. ISSP surveys are assigned to users in the field through the application. Field users then digitally perform multiple actions using the Compliance Manager mobile component on their tablets including:

- Collect CP Test Point Readings

- Add New CP Test Points

- Report Exceptions such as leaks, obstructions, and lock-outs.

Information is relayed back to PG&E for monitoring and verification.

To learn more, see the CP Riser Identification project profile and download our eBook detailing how Cathodic Inspection crews streamlined their inspection process at PG&E.