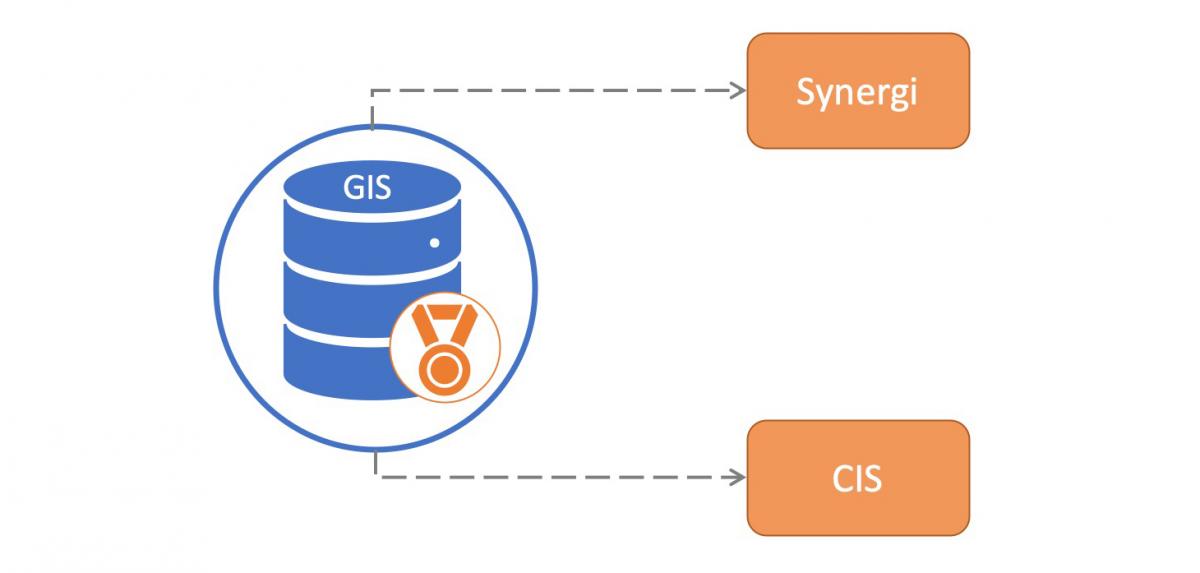

For electric and gas utilities, ensuring customer satisfaction and excellent customer service relies on accurate information from a variety of systems across the Enterprise. Within today’s gas utilities, operators rely on systems such as Geographic Information System (GIS) and Synergi to drive intelligent, efficient decision making for future planning, pipeline replacement programs, and emergency or planned outages.

In today’s technology driven world, it is more important than ever that the data being entered into your GIS can accurately feed the multiple downstream systems it often supports so that accurate information can be given to stakeholders as well as customers.

Content Overview

The Challenge

It’s an industry challenge to ensure that you’re feeding all systems with current, consistent, quality data and can verify data accuracy at any point in time. To reduce the man hours and effort of manual manipulation or massaging of data, it is recommended to enforce a higher degree of quality in the GIS data as it updated and edited. By configuring and customizing your GIS with mandatory Quality Assurance and Quality Check (QA/QC) validation, the user is required to post data to the geodatabase which provides the most benefit to the utility as a whole.

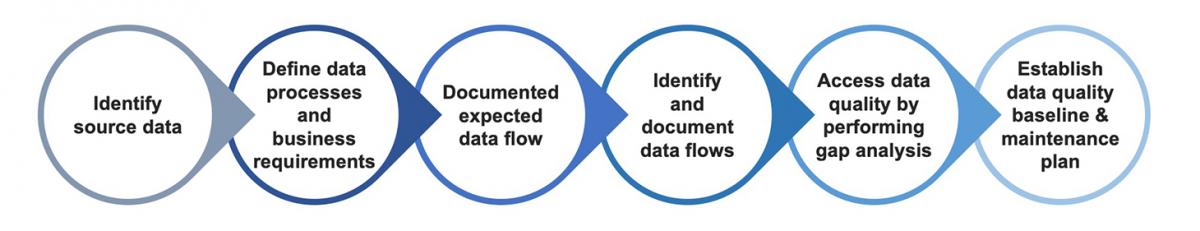

As described in Part 1 of our Enterprise End to End Validation blog series that focuses on the electric utility, tackling this challenge is a multistep process. Ensuring quality from the GIS to downstream systems for gas utilities requires a similar approach and includes the following steps:

- Baseline Data Quality Assessment

- QA/QC Implementation

- Enterprise Validation

Accepting the Challenge

If you want to achieve data that is verifiable, traceable, and correct, you must start with the data you currently have. Questions you will want to ask yourself are:

- What is the state of the data in our GIS? Is it current? Is it complete?

- What is the state of the data in our downstream systems? Is it current? Is it complete?

- What data is needed to feed the downstream systems? And conversely, what data is going to feed our GIS?

- What is the quality and your level of confidence of your data?

- What is the long-term plan to prevent errors from occurring?

To do this as efficiently as possible, a series of tasks should be performed that will support your data’s accuracy and the clean-up process. At a high level, these are:

By asking these questions and putting together an approach that is conducive to your every-day business and client needs, it will allow your utility to establish a single source of data that is the “truth”, rather than having multiple systems that provide data to each other. By establishing a data quality process in your GIS and having a single source of truth for your data, you are ensuring a consistent data flow throughout your systems.

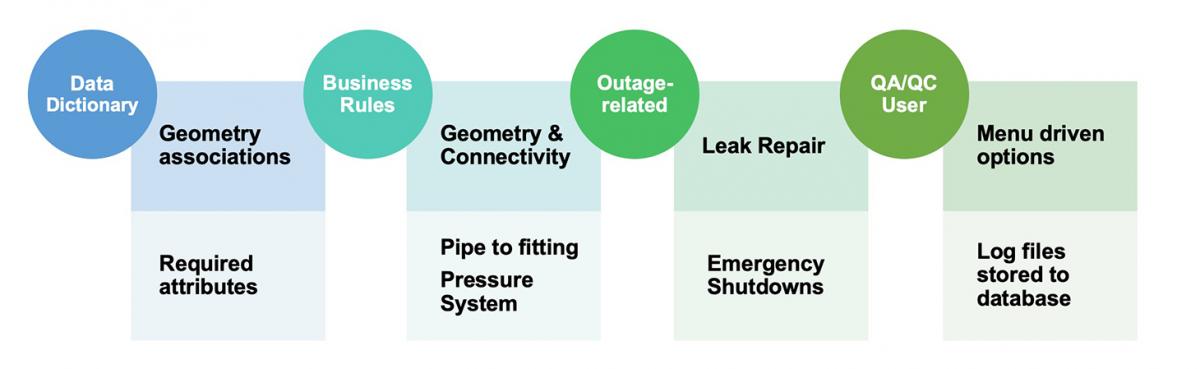

Every utility is unique with their quality requirements, but at a high-level, they can be generally be grouped based on needs. For example:

GIS – Your Foundation

Having quality data, starting at connectivity to provide high confidence outage reporting, and quality attribution to provide consistent reporting are key objectives for your GIS.

There are many ways to achieve quality connectivity and attribution within your GIS. Starting with connectivity, there are many ArcGIS and ArcFM tools that allow you to establish and maintain your connectivity.

Starting with the initial build of your connectivity, it is fairly easy to identify bad geometry, such as self-intersecting lines, with the reporting within the network build. Once this portion of connectivity is done, Schneider Electric’s ArcFM product has a robust suite of tools that will allow you maintain connectivity not only within a specific gas pressure system, but within your gas network as a whole. These are not only powerful tools; they are also easy for end users to operate with minimal training.

Establishing and maintaining consistent, quality attribution in your GIS data is made possible with Schneider Electric’s ArcFM product as well, by allowing you to configure validation from the simplest of levels, such as single attribute validation, all the way to more complex validations, such as verifying that a fitting is connected correctly to the pipes it’s attached to.

Laurel Hill’s GeoData Sentry will also allow you to run both connectivity and attribution checks all in one easy to use suite of tools that are easily configurable and maintainable. These tools also give you to added benefit of updating rules ‘on the fly’ in lieu of configuring them through ArcCatalog. These tools can be used instead of ArcFM rules (not recommended) or as a ‘post-validation’ check to ensure another level of data quality checking.

When these out-of-the-box solutions are not enough, it is possible to write custom routines that will meet your utility’s needs.

An example of this is a maximum allowable operating pressure (MAOP) calculator developed by UDC. This custom-built application uses the utility’s assumption generator and heuristics to assign a MAOP value to every ‘event’ within a gas transmission line based on the Material of the pipe and the percent SYMS, providing an accurate picture of your MAOP within your system making sure it is correct.

Downstream Systems

Customer Information Systems

Most utilities rely on their GIS in some capacity to interface with their CIS and customer billing system. Having good quality GIS data is essential to easily establishing the link between these systems. Having QA/QC in place to check critical attributes such as House Number, Street Name, City and Zip Code populate, and populated consistently and correctly, makes this endeavor much easier and efficient.

Cathodic Protection Systems

For a majority of utilities, this is not a true “downstream” system, but it is increasingly becoming a system within GIS that is being utilized to establish and maintain CP systems within their companies. Schneider Electric’s ArcFM product allows you to build and maintain a complete CP network in GIS.

In order to do this, it is imperative that the underlying data within GIS be correct. Establishing a CP network that has correct connectivity, along with fittings that are attributed correctly, allow the Cathodic Protection Trace functionality to correctly tell you what the status of these systems are.

This functionality uses the underlying CP features captured in GIS, such as Bond Wires, Rectifiers and Test Points, to identify and build a complete picture of your CP systems. Once established, this can become a powerful tool to maintain your CP systems going forward, by identifying any locations where your current systems have breaks in them and allowing you to correct these problems so that your CP systems are correctly built in the real-world and GIS.

Learn about PG&E’s CP initiatives: Automated Cathodic Protection Survey and Modeling Cathodic Protection in Your Enterprise GIS. Download our eBook.

Synergi

In the past, Synergi and GIS were treated as totally separate systems, but more and more it is becoming commonplace for GIS to ‘feed’ the Synergi application. By having GIS being the ‘source of truth’ for Synergi, it allows gas engineers and local offices to communicate better when there is an emergency outage or new construction is being proposed. By utilizing the same data source, it makes this process much easier and efficient.

Running QA/QC validations on your GIS to ensure that your data is accurate provides a much better model for Synergi to use. Synergi uses attributes that are typically maintained in GIS, such as pipe material, diameter, installation year, etc. to build its models.

Having accurate data in GIS to feed Synergi allows for a more accurate model to be built, allowing for a higher confidence with gas engineers that they are correctly designing systems for customers and construction.

Validation Designed and Built for Your Needs

With consistent, verifiable and accurate reporting at the forefront of today’s gas utility, it is more important than ever that your GIS reflect what is truly ‘in the ground’ so that you confidently provide these reports. By putting in place a plan that allows QA/QC to be run often and consistently, you can assure that the information you provide is of the utmost quality, thus reducing your risk and making your customer confidence industry leading.

We invite you to contact us to learn more about QA/QC and Enterprise Validation or how we can help you maintain your digital asset data. Read Part 1 of our Enterprise End to End Validation series to learn about the electric side.